The Trend of Supply Source Diversification after Global Disruptions: Choice or Necessity?

English - Ngày đăng : 15:43, 08/07/2025

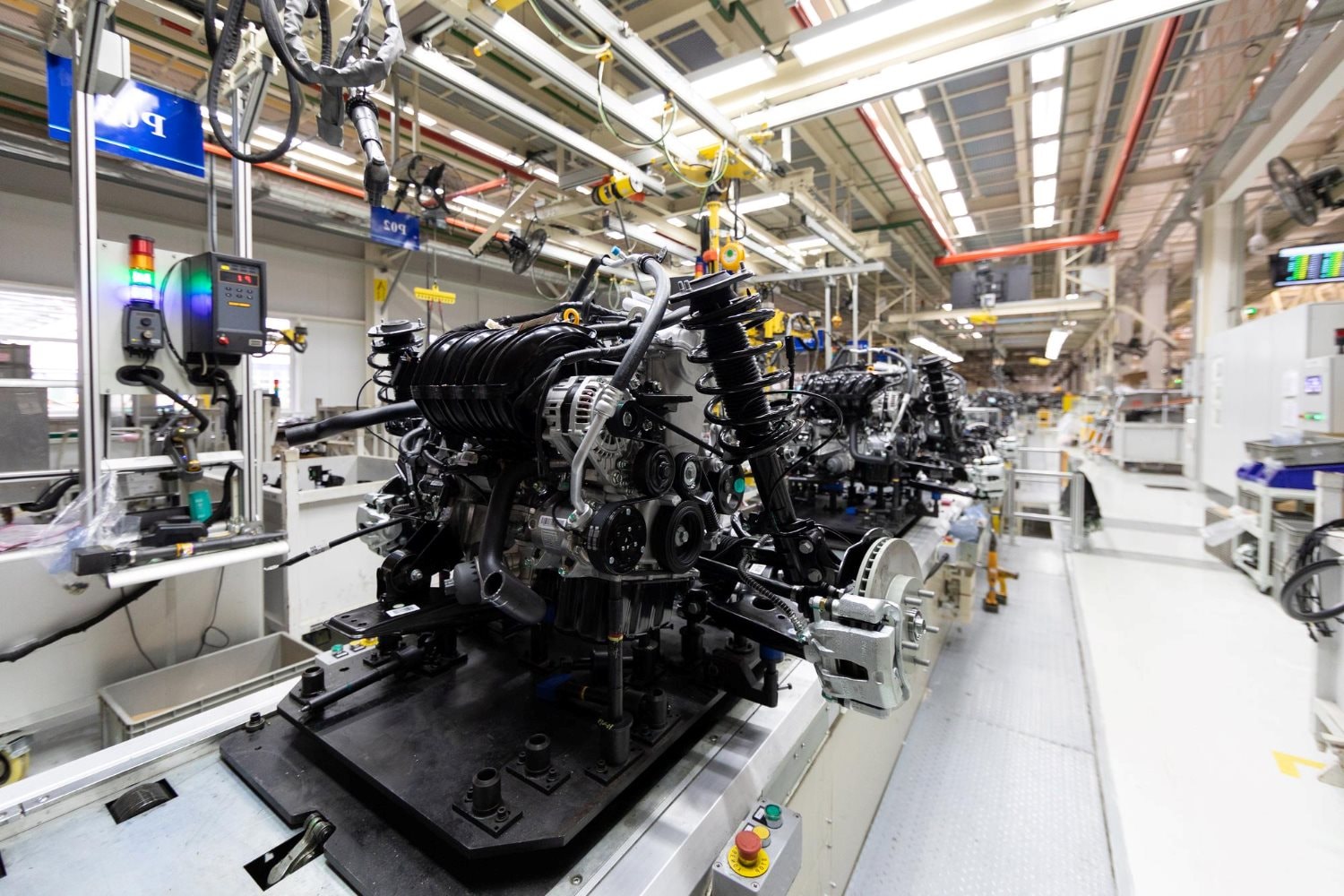

Previously, cost optimization drove businesses to prioritize single sourcing. However, after painful lessons from the COVID-19 pandemic, the U.S.-China trade war, and the global chip shortage, supply source diversification (multi/dual sourcing) is no longer optional but a vital survival strategy.

The Issue with Single Sourcing

Single sourcing—relying on a single primary supplier—used to optimize costs, reduce negotiation efforts, increase order volume for better pricing, and strengthen partner relationships. Yet, this very “concentration” becomes a critical weakness during supply chain disruptions. A factory shutdown, a blocked logistics route, or a sudden export policy change can bring production to a halt.

In fast-paced industries like electronics, automotive, or pharmaceuticals, passively waiting for materials not only causes revenue loss but also diminishes competitiveness. Even giants like Toyota, Apple, and Pfizer have struggled due to dependence on strategic suppliers in Asia.

Advantages and Disadvantages of Multi-Sourcing

Diversifying supply sources allows businesses to spread risk, increase flexibility, and better manage operations. When disruptions hit one region, companies can shift orders to other partners. This not only maintains material flow but also strengthens negotiation power by avoiding reliance on a single source.

However, multi-sourcing comes at a cost. Managing multiple suppliers means higher transaction costs, increased workload for procurement and supply chain teams, and risks of inconsistent product quality. Real-time ERP data integration becomes more complex, and legal risks can arise if oversight is lacking.

Therefore, businesses need a clear strategy to implement this model effectively—choosing suppliers by region (regional sourcing), categorizing suppliers by role (core vs. backup), and adjusting production plans to match each source’s capacity.

Risk must be designed into the supply chain from the product development phase to proactively adapt to global changes.

Supplier Risk Assessment Tools

Supply diversification must be data-driven, not based on intuition. Key indicators like political stability, production capacity, geographic location, information security, ESG compliance, and order fulfillment history should be part of a supplier scoring model.

Tools such as supply chain mapping, FMEA (Failure Mode and Effects Analysis), and supply chain risk management (SCRM) platforms are being adopted by many companies to identify vulnerabilities and establish contingency plans. This ensures that businesses have not just “more sources,” but “the right and ready sources.”

Exporting businesses especially must ensure compliance with origin regulations, quality control, and international standards when changing suppliers. Switching suppliers must go hand-in-hand with training, monitoring, and auditing the entire process.

In today’s unpredictable global business environment, no supply model is flawless. The key is for businesses to shift from a cost-optimization mindset to one of overall adaptability. Supply source diversification is not only a risk mitigation tactic but also a foundation for building a resilient value chain.

We believe Vietnamese enterprises—especially export-oriented manufacturers—should promptly reassess their current sourcing models. Investing in risk assessment tools, building controlled diversification strategies, and developing a supplier ecosystem aligned with internal capabilities will be a long-term path forward. When a company is no longer dependent on a single link, that’s when it truly owns a flexible supply chain ready to adapt to any global market fluctuation.