Vietnam’s Logistics Workforce: From Manual Labour to Digital Supply Chain Architects

English - Ngày đăng : 08:37, 04/02/2026

Companies no longer need only document clerks, dispatchers and warehouse hands; they need “supply chain architects” who can design networks, read data and work with multiple stakeholders at a strategic level. The question is where Vietnam stands on this transformation journey and what must be done to avoid missing the window of opportunity to upgrade its logistics workforce.

From manual roles to multi-layered career paths

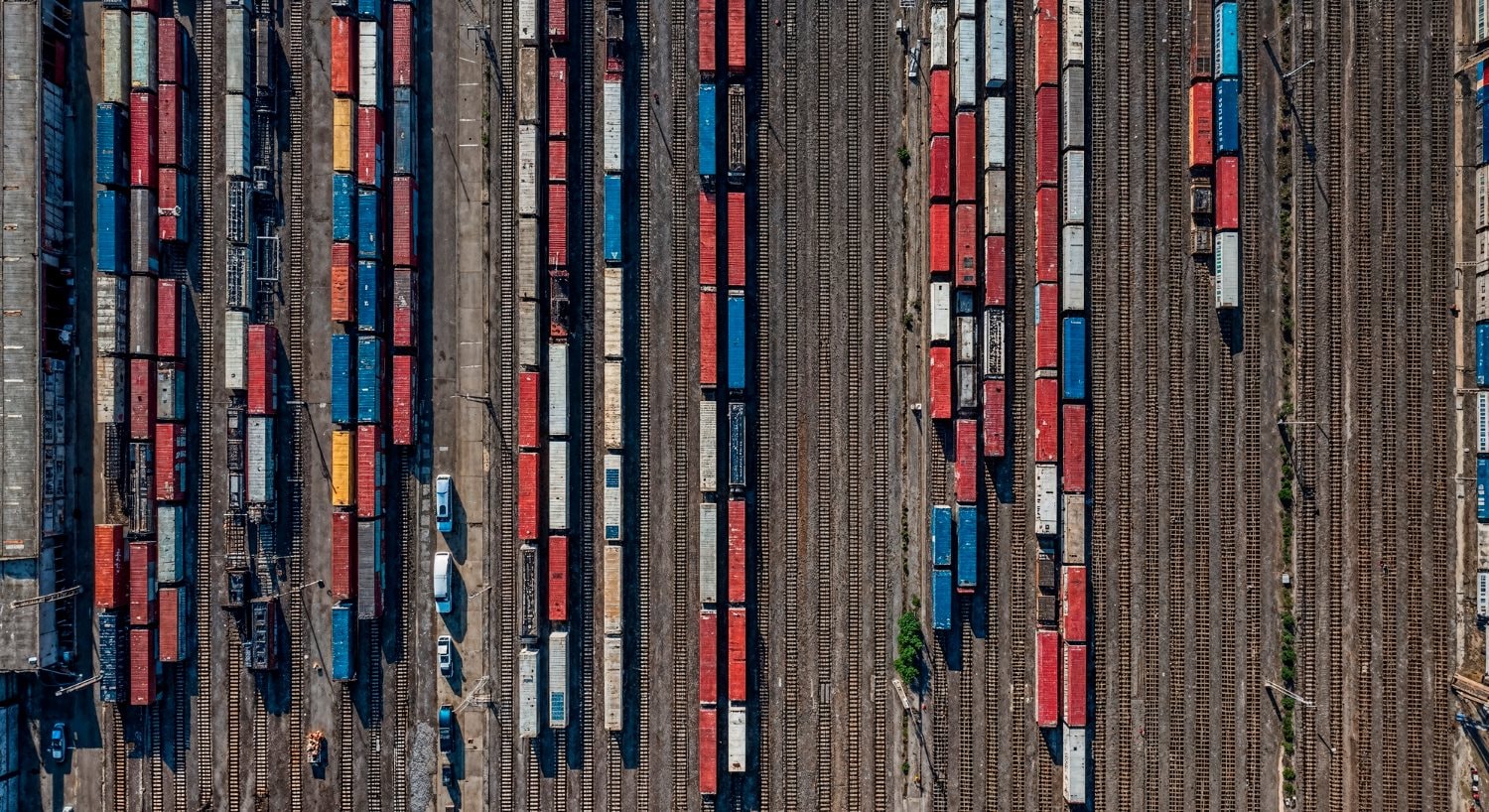

A decade or so ago, most logistics jobs in Vietnam clustered at the frontline: drivers, loaders, warehouse operators, field staff and basic documentation clerks. Logistics largely meant transport and traditional freight forwarding; investment in automation and digital systems was limited, and “supply chain management” was a term found mainly in FDI manufacturers and a handful of large domestic firms.

Today, the picture is shifting. Many 3PLs, 4PLs and export-oriented manufacturers are reorganising around end-to-end supply chain logic: demand planning, production planning, network design, inventory management, transport optimisation and supplier management. This naturally produces a more layered talent structure: frontline operational staff; planners and dispatchers; data analysts and continuous improvement specialists; and project managers and solution designers who work directly with customers.

The challenge is that this shift is happening faster than the education and training system can adapt. Many graduates in logistics and supply chain majors are strong on theory but weak on practical skills: limited exposure to TMS, WMS and ERP systems, and insufficient ability to interpret operational data and turn it into decisions. On the other side, a large pool of experienced practitioners lacks digital literacy and familiarity with concepts such as ESG, Net Zero and cross-border e-commerce, making it difficult for them to move into higher-value roles.

Skill gaps in the era of digitalisation and ESG

When companies talk about digital transformation or Net Zero in logistics, the core challenge is often not buying software or replacing trucks, but changing how operations are planned and decisions are made. To make that shift, they need people with hybrid skills: a solid grasp of logistics processes, the ability to use data and digital tools, and an understanding of ESG and environmental and social standards imposed by global customers on their supply chains.

The skills gap appears at multiple levels. At the operational level, drivers, warehouse operators and dispatchers need to become comfortable using handheld devices and mobile apps, reading digital work orders instead of paper instructions. At the planning level, staff must be able to use routing and network optimisation tools, analyse costs and set up performance indicators. At the management level, supply chain leaders need to know how to measure carbon footprints, assess network risks, design contingencies and integrate data from many sources into coherent decisions.

Soft skills are also more critical than ever. Supply chains are multi-actor systems involving suppliers, carriers, logistics providers, factories, retailers and regulators. Logistics professionals cannot simply “follow orders”; they must negotiate, explain solutions, manage incidents and maintain transparency and trust in communication. The combination of technical, digital and interpersonal skills is the passport that will allow Vietnam’s logistics workforce to compete in a landscape where the battle is not only between companies but also between teams and capabilities.

A new training ecosystem: linking business, academia and associations

Closing these skill gaps is beyond the capacity of any single actor. International experience shows that countries with strong logistics sectors tend to have multi-layered training ecosystems, where businesses, universities, vocational colleges and professional associations all play defined roles.

In Vietnam, universities, colleges and training centres need to keep updating curricula towards greater practical relevance: more simulation, project-based learning with real companies, and more internships in operational environments. New topics such as cross-border e-commerce, green logistics, supply chain finance and risk management should be embedded. Logistics companies and exporters need to proactively “place orders” with training providers, participate in curriculum design, second experienced practitioners as guest lecturers and expand internship and trainee programmes as a pipeline for future hires.

Industry associations and professional bodies can act as coordinators in this ecosystem: developing competency frameworks for key supply chain roles; offering short courses and executive programmes to update practitioners on new trends; and building career mentoring networks for students and young professionals. On the policy side, government support for reskilling and upskilling programmes targeted at logistics workers, co-funded training schemes for SMEs and international cooperation projects in logistics education can all accelerate the talent transition.

Vietnam’s logistics workforce stands at a crossroads. It can either remain stuck in low-value, manual roles dependent on cheap labour, or evolve into a cadre of digital supply chain architects capable of competing regionally and globally. The difference will be shaped not only by wages and job titles, but by whether the country is willing to invest seriously in new skills, new training models and stronger linkages between businesses, academia and professional associations.

In national strategies to enhance logistics competitiveness, hard infrastructure – ports, roads and warehouses – matters greatly, but soft infrastructure – people – matters even more. When Vietnam’s logistics workforce is equipped with a hybrid skillset that blends operational know-how, digital literacy and ESG awareness, supported by a training ecosystem closely aligned with real business needs, the opportunity for a step-change in performance becomes tangible. This is not just a chance to improve incomes for hundreds of thousands of logistics workers; it is also a chance for Vietnamese firms to move up the global value chain – from basic transport and forwarding to designing and operating integrated supply chain solutions as trusted partners on the regional and global stage.