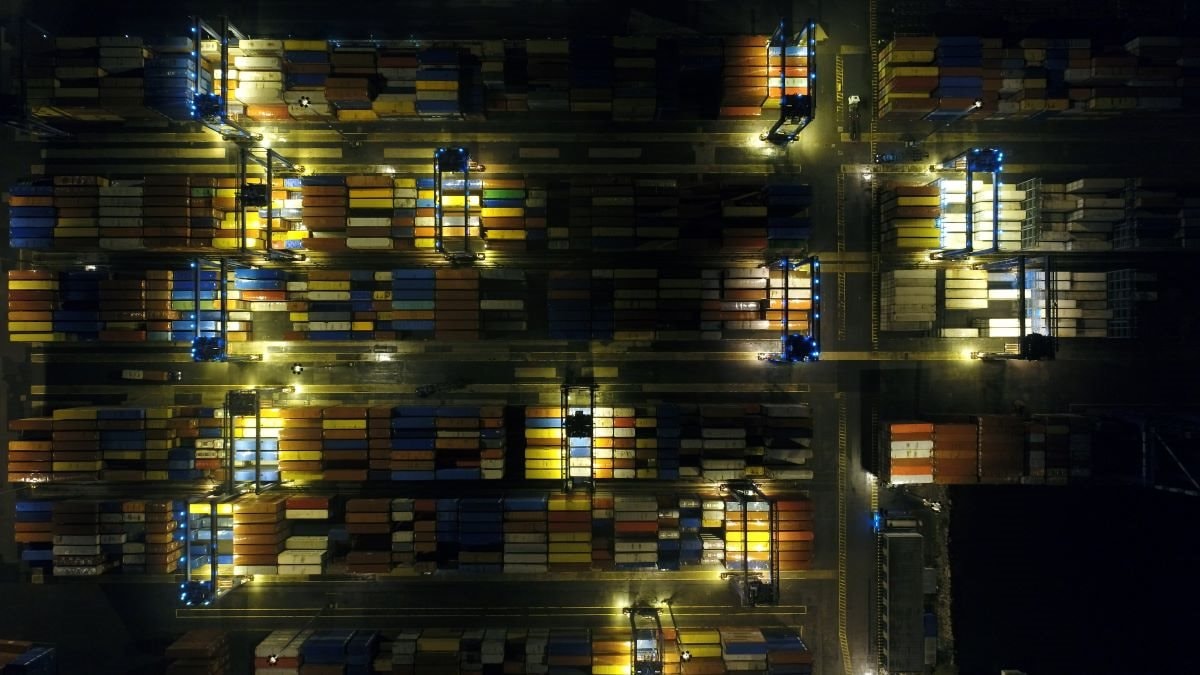

Today, businesses face more pressure than ever to adapt quickly and flexibly. The supply chain the "backbone" of production and commerce is where the need for transformation is most evident. The year 2025 will be a pivotal moment when organizations must restructure, embrace technology, and develop a sustainable mindset to build a more resilient supply ecosystem for the future.

Diversification and Risk Reduction

More than ever, overreliance on a single market or supplier has become a major risk. The U.S.-China trade war, the COVID-19 pandemic, and the recent Russia-Ukraine conflict have severely disrupted global supply chains. According to a survey by The Conference Board, 85% of business leaders plan to adjust their supply chain strategies in 2025—a sharp increase compared to 2023.

Companies are actively implementing the “China +1” strategy—seeking one or more alternative countries to China for production. Vietnam, India, and Mexico have emerged as top alternatives due to cost advantages, favorable policies, and strategic locations.

At the same time, trends like “nearshoring” and “reshoring” are gaining traction, bringing production facilities closer to end markets to shorten delivery times, reduce logistics costs, and improve quality control.

Apple is a prime example, expanding iPhone assembly to India and Vietnam to ensure operations remain uninterrupted amid political shifts. Likewise, many small and medium-sized enterprises are adopting risk-distributed models to enhance long-term resilience.

AI and Digital Transformation

In the digital age, technology is not just supportive but decisive in supply chain success. Artificial Intelligence (AI) is increasingly used for demand forecasting, inventory optimization, operational automation, and risk analysis. According to IBM, around 60% of global CEOs expect AI to replace most manual processes within the next five years.

Corporations like Amazon and Walmart have adopted AI to manage smart warehouses, track shipments in real-time, and personalize customer experiences. Blockchain technology also enhances transparency, enabling consumers to trace products from origin to end-user.

Though still emerging, the metaverse is being used to simulate supply chain operations in virtual environments. Logistics firms can test warehouse layouts, train staff, and manage emergency scenarios without real-world costs.

McKinsey estimates that successful digital transformation in supply chains can improve efficiency by up to 20% and reduce operating costs by 30%—a significant advantage in today’s fiercely competitive market.

Climate Change and Cybersecurity Challenges

Climate change is becoming an unavoidable factor in supply chain planning. Floods, wildfires, droughts, and extreme weather are increasingly common, causing severe disruptions to freight transport, agricultural harvests, and warehousing operations. A report by Everstream Analytics shows that over 90% of businesses see climate change as the greatest threat to global supply chains.

This has led to the rise of the “green supply chain,” aimed at reducing emissions, using eco-friendly materials, and improving transport efficiency. Companies like Unilever, Nestlé, and Microsoft have committed to carbon neutrality by 2030, including their supply chain operations.

Simultaneously, cybersecurity has emerged as a critical threat. In tightly connected ecosystems of suppliers, distributors, and customers, a single cyberattack on one link can cripple the entire system. In 2023, more than 30% of businesses experienced supply chain-related cyberattacks—a 22% increase from the previous year.

To counter this, organizations are deploying multi-layered security, enhancing data encryption, and training employees to recognize cyber threats. Collaborating with tech firms to build secure digital infrastructure has become an urgent necessity.

The supply chain in 2025 is no longer just about transport and distribution—it’s a strategic game of data, technology, and sustainable thinking. Companies that proactively adapt, diversify supply sources, invest in digital transformation, and effectively respond to climate and cybersecurity crises will lead the global race.

The future does not belong to the stagnant. Supply chains must not only “recover” but be “redefined”—agile, digitalized, green, and secure. This is the foundation for a new world of production and consumption that is taking shape.